Ultimate Guide To Gravely Zero Turn Mower Troubleshooting

If you own a Gravely zero-turn mower, you know how valuable it is for maintaining your lawn. These machines are renowned for their efficiency and durability. However, even the most reliable equipment can run into issues from time to time. Troubleshooting a zero-turn mower may seem daunting, but with a structured approach, you can identify and resolve many common problems yourself. In this comprehensive guide, we’ll cover the most frequent issues you might encounter with your Gravely zero-turn mower and provide step-by-step solutions to get your mower back in top shape.

Understanding Your Gravely Zero Turn Mower

Gravely zero-turn mowers are designed for optimal maneuverability and cutting precision. They use a unique steering mechanism with independent wheel control, which allows them to make sharp turns and navigate around obstacles with ease. However, their complexity can sometimes lead to specific problems that require troubleshooting.

Common Problems and Solutions

1. Mower Won’t Start

Possible Causes:

- Battery Issues: The battery might be dead or not properly connected.

- Fuel Problems: You might be out of fuel or the fuel might be old or contaminated.

- Safety Switches: The safety switches, such as the seat switch or blade engagement switch, might be malfunctioning.

Solutions:

- Check the Battery: Ensure the battery terminals are clean and tightly connected. Use a multimeter to check the battery voltage. If it’s low, try jump-starting or replacing the battery.

- Inspect Fuel System: Verify that there is enough fresh fuel in the tank. Check for fuel leaks and replace old or contaminated fuel with fresh gasoline.

- Examine Safety Switches: Ensure that all safety switches are in the correct position. Sometimes, engaging and disengaging the switches a few times can resolve the issue.

2. Engine Starts but Stalls

Possible Causes:

- Clogged Air Filter: A dirty or clogged air filter can restrict airflow to the engine.

- Fuel Filter Blockage: A blocked fuel filter can prevent fuel from reaching the engine.

- Spark Plug Issues: Worn or fouled spark plugs can cause engine stalling.

Solutions:

- Replace Air Filter: Check the air filter and replace it if it’s dirty. A clean air filter will ensure optimal airflow to the engine.

- Check Fuel Filter: Inspect and replace the fuel filter if it’s clogged. Regular replacement of the fuel filter is essential for smooth engine performance.

- Inspect Spark Plugs: Remove the spark plugs and examine them. Replace any worn or damaged spark plugs to ensure proper engine firing.

3. Uneven Cutting

Possible Causes:

- Uneven Tire Pressure: Differences in tire pressure can affect the mower’s cutting height.

- Blades Dull or Damaged: Dull or damaged blades can cause an uneven cut.

- Deck Leveling Issues: An improperly leveled cutting deck can result in an uneven cut.

Solutions:

- Adjust Tire Pressure: Check and adjust the tire pressure according to the manufacturer’s specifications. Even pressure helps maintain a consistent cutting height.

- Sharpen or Replace Blades: Inspect the blades for sharpness and damage. Sharpen the blades regularly, and replace them if they’re excessively worn.

- Level the Deck: Adjust the cutting deck to ensure it is level. Follow the manufacturer’s instructions for deck leveling to achieve an even cut.

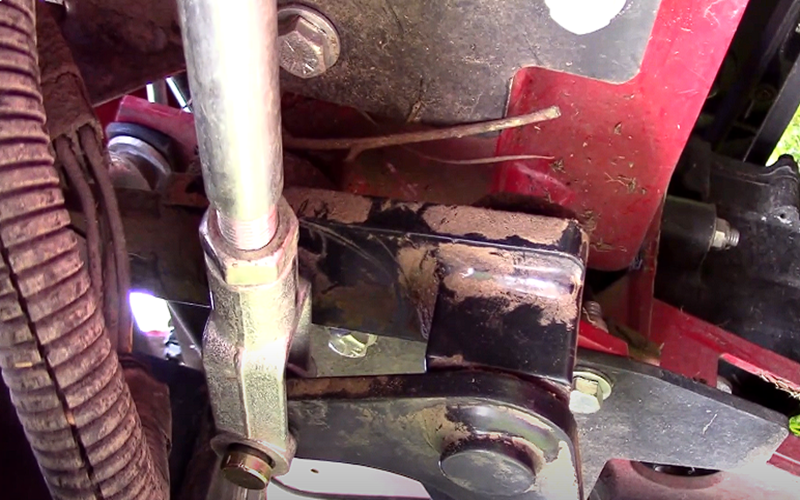

4. Transmission Issues

Possible Causes:

- Low Fluid Levels: Low transmission fluid can cause poor performance or failure.

- Hydraulic Leaks: Leaks in the hydraulic system can lead to transmission problems.

- Drive Belt Problems: A worn or broken drive belt can affect the transmission’s function.

Solutions:

- Check Transmission Fluid: Inspect the transmission fluid level and top it off if necessary. Ensure that you use the recommended fluid type for your mower.

- Inspect for Leaks: Check the hydraulic system for any signs of leaks. Repair or replace any damaged hydraulic components.

- Examine Drive Belts: Inspect the drive belts for wear and tear. Replace any broken or frayed belts to restore proper transmission function.

5. Steering Problems

Possible Causes:

- Wheel Alignment Issues: Misaligned wheels can make steering difficult.

- Hydraulic Steering Issues: Problems with the hydraulic steering system can affect maneuverability.

- Loose Steering Components: Loose or worn steering components can lead to steering difficulties.

Solutions:

- Adjust Wheel Alignment: Check the alignment of the wheels and adjust as needed. Proper alignment ensures smooth steering and maneuverability.

- Inspect Hydraulic Steering: Check the hydraulic steering system for any issues, such as low fluid levels or leaks. Address any problems to ensure proper steering function.

- Tighten Steering Components: Inspect and tighten any loose steering components. Regular maintenance of steering parts helps prevent steering problems.

Preventative Maintenance Tips

Preventative maintenance is crucial for keeping your Gravely zero turn mower in optimal condition. Regular upkeep can help prevent many common issues and extend the life of your mower.

- Regular Cleaning: Clean the mower deck and remove any grass or debris buildup. This helps prevent clogs and ensures efficient operation.

- Oil Changes: Change the engine oil and oil filter regularly to keep the engine running smoothly.

- Blade Maintenance: Sharpen or replace mower blades as needed to maintain cutting efficiency.

- Check Belts and Hoses: Regularly inspect and replace any worn belts or hoses to prevent breakdowns.

When to Seek Professional Help

While many issues can be resolved with basic troubleshooting, there are times when professional assistance is required. If you encounter complex problems or if your troubleshooting efforts don’t resolve the issue, it’s best to consult a qualified technician. They have the expertise and tools necessary to diagnose and repair more intricate problems.

Conclusion

Troubleshooting your Gravely zero turn mower can seem overwhelming, but with the right approach, you can address many common issues yourself. By understanding potential problems and their solutions, you can keep your mower running efficiently and effectively. Regular maintenance and timely repairs will help ensure that your Gravely zero-turn mower continues to deliver exceptional performance for years to come. If you ever find yourself stumped, don’t hesitate to reach out to a professional for assistance.

Michael Anderson is a lawn care professional with many years of experience in the industry. His journey began in his family’s landscaping business, where he developed a passion for gardening and outdoor maintenance. Michael specializes in helping homeowners tackle challenging terrain, focusing on the best equipment and techniques for effective lawn care.

In 2024, he founded bestzeroturnmowerforhills.com to share his knowledge and help others find the ideal zero turn mower for hilly landscapes. His commitment to providing unbiased reviews and practical advice has made him a trusted resource for gardening enthusiasts.